|

|

Plasma Cutting Machine |

|---|

2 15 inch Touch Screen

3 USB and Network transmission

4 All weld structure

Plasma arc cutting basic introduction

Plasma arc cutting is a high-speed plasma arc as the heating source, the metal is heated to melting and blown away by the high-speed airstream at the same time to form a narrow slit. The plasma unit generates the plasma arc, the current density is extremely high, a very narrow straight plasma flame, narrow kerf, smooth cutting surface, cut perpendicular to the edge, the cutting accuracy and surface quality close to the laser cutting.

The main advantages is that,

1. No dross, the cutting speed has wide range, and good cut quality.

2. The cutting speed can be increased 30% under the same power supply, avoid incision nitridation problem, the workpiece has a good welding and processing performance.

Main features of Plasma Cutting Machine:

1. 15” full touch screen man-machine dialogue operation, simple and intuitive

2. Curable WindowXP system, a new generation of CNC software based on Microsoft.net technology

3. Arbitrary two-dimensional graphics cutting

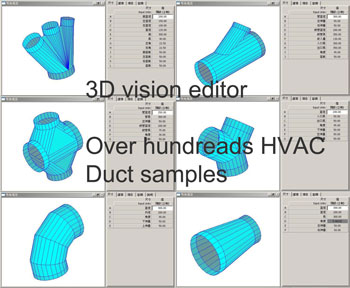

4. Supporting three-dimensional graphics automatically decompose cutting

5. Self-diagnostic function with error display

6. Dynamic graphic simulation (pre-demo) function

7. CNC / coordinate / test status selection function

8. Universal Plasma Interface, varieties of plasma power supply.

9. Can be modified to define the cutting direction and piercing point

10. Flexible setting plate size, to avoid material waste handling may cause

11. Local system with programming, layout, nesting

12. Hundreds of ventilation ducts arbitrary choice of supporting graphics available to customers

13. Real-time motion graphics and input / output data

14. Dynamic Graph tracking function

15. English or Metric units switch

16. Reset & Return function

17. USB connection, support for external programs directly copied

18. Network transmission interface

Structural characteristics and standard machine configuration

1. The frame is all welded steel structure, which is overall processing after ageing treatment.

2. X-axis, Y-axis mounting precision linear rails, the sheet metal support bars is made up of plug-in sheet for easy replacement and clean up.

3. The driven system is high precision gear rack transmission, equip with the stepping motor.

4. The industrial motherboard is chosen considering the high requirement for anti-electromagnetic radiation, anti-seismic capacity

5. Industrial grade TFT LCD 15-inch full touch screen.

6. Configure industry standard CNC dedicated keyboard, and with a dedicated controller sensitivity

Equipment working environment:

◆ Power requirements: three-phase AC 380V (± 10%), 50Hz (± 2%)

Single phase 220V (± 10%), 50Hz (± 2%). Other power supply is on request.

◆ Temperature: -5 ℃ ~ +45 ℃

◆ Relative humidity: ≤ 95%

◆ Altitude: 1000M less

◆ Installation site: clean, less dust; ventilation; away from the source of vibration

◆ Gas Supply:

Compressed Air

Pressure must be reached than 0.4MP, humidity, flow

| Technical Data | |||

|---|---|---|---|

| Model | PC3100 | PC5100 | PC6000 |

| Processing Capacity | Standerd 0.5~6mm Copper,aluminum,stainless steel | ||

| Cutting Speed | Up to 10m/min | ||

| Working tolerance | ±0.5mm in length/±0.8mm in mdiagonal | ||

| Cutting Area | 1250x3100mm | 1250x5100mm | 1250x6000mm |

| Working Area | 1350x3900mm | 1350x5900mm | 1350x6900mm |