Hydraulic Press Brake

Precise, High-speed, Easy to handel

J&K Press Brakes are highly productive, precise, easy to handel. Based on years of expericen on metal processing, JK offers qualified Hydraulic Press Brakes for thousands of customers.

J&K Press Brakes are going to be your most skilled assitant for your metal bending job, with them help, you just need to input your design, and then, let the machines do for you, free your eyes and hand, just enjoy yourself, say goodbye to the hard work forever.

When you purchase the our Press Brakes, you got not only machines, but the promise from our company, we will supply you the life time service in the future everyday since you got the machines.

Range from 40 Tons to 800 Tons

The tonage range from 40 Tons to 800 Tons, (How to calculate the force that you want? click here) no matter you will processing the 0.4mm painted steel or 16 mm carbon steel, our machine will give you the best solution.

Reinforced frame construction

All steel welded structure,vibrating treatment of ageing for removal of internal stress with high strength and good rigidity.

Precise Ram Stroke

High-speed Hydraulic system

Integrated hydraulic transmission system special designed from professional supplier, large range of speed regulation to transmission of the slide block, stable and reliable performance.

In order to run quietly, the internal gear pump is a reliable choice. Quiet like in the library, we can make the noise sound level less than 65 dB (Even more quiet than in the street).

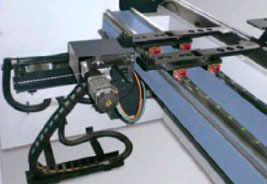

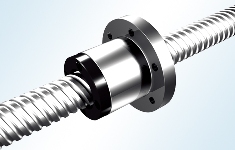

Backgauge System

Backgauge and the slide block have electrical adjustment for their stroke with manual fine tuning and digital indication. The ball screw assemly for transfer the backgauge choose the Ball Screw-Inner Cycle, end cap type, which replaces the traditonal transfer mode that screw shaft and nut effect directly, therefore the minimum rolling friction takes place of the sliding friction of traditonal screw. The transfer efficiency of ball screw will reach more than 90%.

Precision Slides

Adjustment mechanism of slide block independent from oil cylinders' assembly to enhance sealing effect,upper matrix is fitted with fine tuning mechanism.

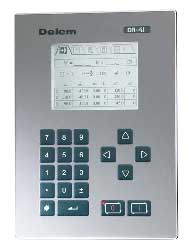

Delem CNC system

|

|

|

||||

Delem DA41 |

Delem DA56 |

Delem DA65 |

||||

| Conventional press brake solution | Powerful & Economic Solution | User-friendliness | ||||

| Featuring | Featuring | Featuring | ||||

| Bright LCD display | 2D graphical programming | 2D graphical programming | ||||

| Beam stop control | 10,4" TFT color LCD | 3D visualisation in production mode | ||||

| Backgauge control | Bend sequence determination | 10" TFT color display | ||||

| Angel programming | Developed length calculation | Full Windows suite | ||||

| Tool Programming | Crowning control | USB Keyboard& mouse interface | ||||

| Retract function | USB peripheral interfacing | User specific application | ||||

| Up to 100 programs | Network interface | Sensor bending & correction interface | ||||

| Up to 25 bends per program | Tandem operation | USB flash memory drive | ||||

| Panel based housing | Product Memory 32 MB | Product & tool memory 64 MB |

Slide block (axis Y) and backgauge (axis X) is controlled by DELEM CNC system,with ball screw and liner guide,driven by Seimens servo motor .

Choose the right Press Brakes for your business

| Model | Tonnage | Length of Bed | Distance Between Housings | Throat | Ram Stroke | Shut Height | Dimension |

|---|---|---|---|---|---|---|---|

| Unit | KN | mm | mm | mm | mm | mm | mm |

| WC67K-40/2200 | 400 | 2200(7 feet) | 1650 | 200 | 100 | 340 | 2280*1470*2100 |

| WC67K-40/2500 | 400 | 2500(8 feet) | 2000 | 250 | 100 | 340 | 2580*1470*2100 |

| WC67K-63/2500 | 630 | 2500(8 feet) | 2000 | 250 | 100 | 370 | 3300*1725*2300 |

| WC67K-80/3200 | 800 | 3200(10 feet) | 2490 | 250 | 120 | 380 | 3300*1725*2350 |

| WC67K-100/3200 | 1000 | 3200(10 feet) | 2490 | 320 | 120 | 400 | 3290*1740*2400 |

| WC67K-125/4000 | 1250 | 4000(13 feet) | 3000 | 320 | 120 | 400 | 4080*1740*2400 |

| WC67K-160/3200 | 1600 | 3200(11 feet) | 2490 | 320 | 180 | 450 | 3280*1930*2600 |

| WC67K-160/6000 | 1600 | 6000(20 feet) | 4100 | 320 | 180 | 450 | 6080*1980*3100 |

| WC67K-200/4000 | 2000 | 4000(13 feet) | 3000 | 320 | 200 | 470 | 4080*1930*2700 |

| WC67K-200/6000 | 2000 | 4500(15 feet) | 4600 | 320 | 250 | 470 | 6080*2180*3180 |

| WC67K-250/3200 | 2500 | 3200(10 feet) | 2490 | 400 | 250 | 540 | 3280*2510*2800 |

| WC67K-250/6000 | 2500 | 6000(20 feet) | 4600 | 400 | 250 | 540 | 6080*2280*3280 |

| WC67K-300/4000 | 3000 | 4000(13 feet) | 3000 | 400 | 250 | 560 | 4080*2200*3100 |

| WC67K-400/5000 | 3000 | 4000(13 feet) | 3000 | 400 | 250 | 560 | 4080*2200*3100 |

| WC67K-500/6000 | 5000 | 6000 | 4400 | 350 | 250 | 600 | 6080*2400*3300 |

| WC67K-600/6000 | 6000 | 6000 | 4600 | 350 | 300 | 700 | 6080*2500*3600 |